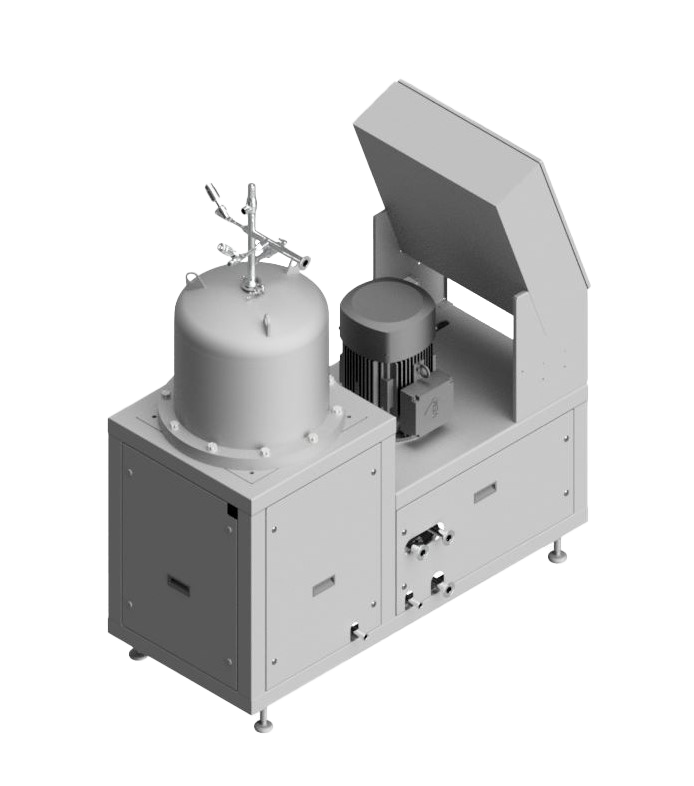

NDCF 3

Filtration System NDCF 3

Filter Area 3 m²

NDCF filtration is designed for industrial purposes and utilizes special ceramic filter discs with nanopore technology to enable highly efficient filtration of liquids and gels. With this technology, particles and impurities as small as a few nanometers can be removed, allowing for very precise cleaning and concentration of products.

Dynamic Cross Flow Filtration is a state-of-the-art filtration technology used in various industries such as food, chemical, pharmaceutical, and biotech. It allows for precise and efficient separation of solids and liquids. These filtration systems are capable of effectively removing particles or proteins of different sizes.

The technology enables continuous filtration and can effectively remove a variety of particle sizes, achieving concentration and purification of products that are not only high-quality but also cost-effective.

novoflow GmbH is a global leader in Dynamic Cross Flow Filtration, offering a wide range of solutions for various applications. Our experts assist you in selecting the right equipment and solutions, providing support during installation and commissioning. We take pride in taking a pioneering role in Dynamic Cross Flow Filtration with our expertise and commitment to quality and customer service.

Haven't found the right filtration system yet? Configure your customized Dynamic Cross Flow Filtration system with our assistance!

Advantages

- A large selection of different pumping methods from diaphragm pumps, progressive cavity pumps, centrifugal pumps, piston pumps, as well as pumps according to customer requirements.

- You can rely on well-known sensor manufacturers such as Seli, Endress & Hauser, Ifm, Brauner, Festo, SMC.

- Would you like to expand your production? No problem, the filtration system can grow with you thanks to its modular design.

- The dynamic cross-flow filtration process can achieve an up to 200 % higher solids concentration compared to standard cross-flow filtration.

- Gentle product processing as filtration takes place in the pressure range from 1 to 4 bar.

- Various pore sizes: 3 nm, 5 nm, 10 nm, 50 nm, 70 nm, 100 nm, 200 nm, 0.4 µm, 0.8 µm and 1.1 µm

- With optional automated Cip cleaning, adjustable according to your requirements.

- Up to 6 different filtration sequences can be stored for different products.

- You can freely select the size of the filter surface from a 15 m² system in 5 m² steps.

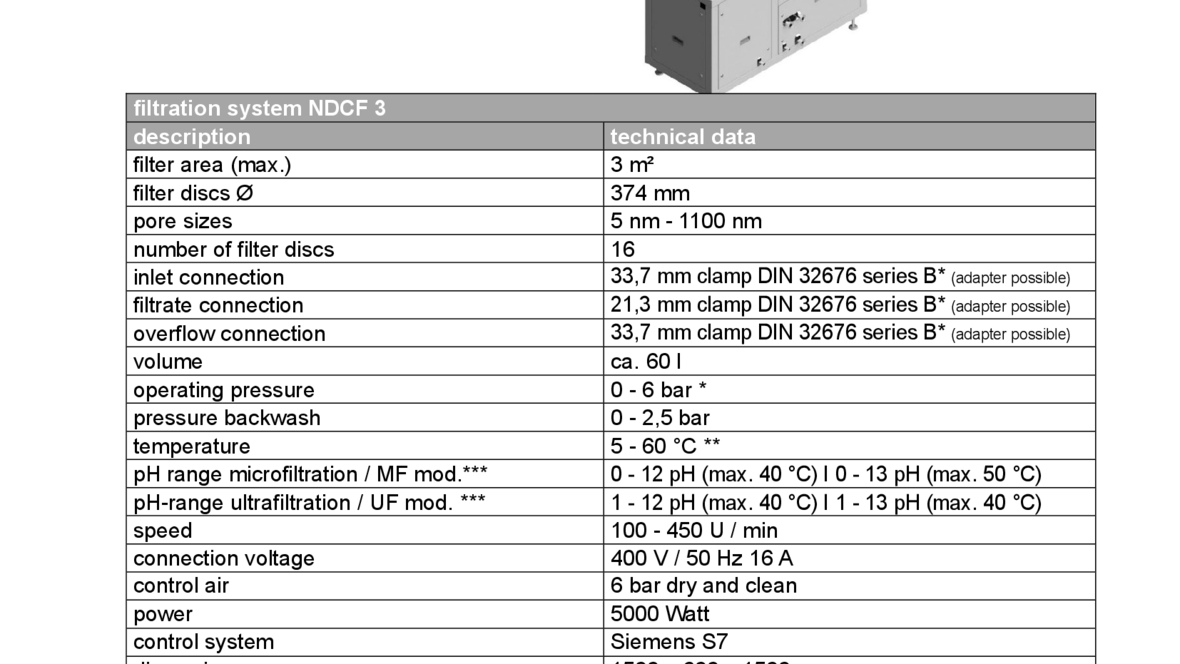

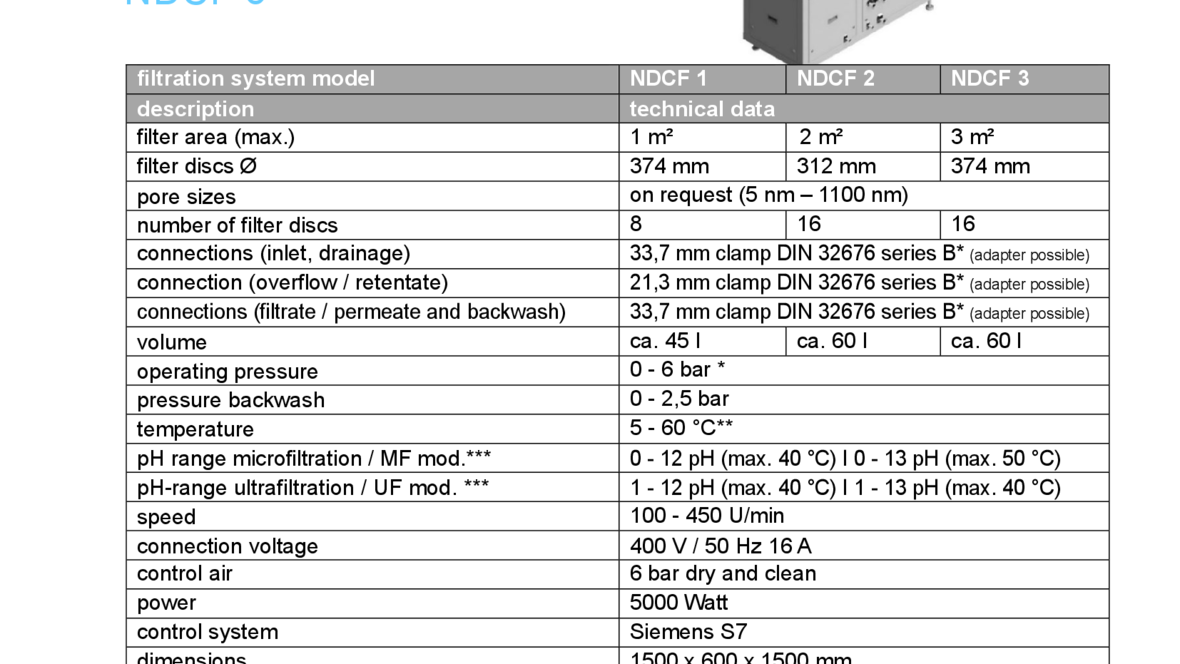

| Filter area | 3 m² |

|---|---|

| Filter discs | 374 mm |

| Pore sizes | 3 nm, 5 nm, 10 nm, 50 nm, 70 nm, 100 nm, 200 nm, 0.4 µm, 0.8 µm and 1.1 µm |

| Number of filter discs | 16 |

| Connections inflow | 33.7 mm clamp DIN 32676 series B* (adapter possible) |

| Connections overflow | 33.7 mm clamp DIN 32676 series B* (adapter possible) |

| Connections filtrate | 21.3 mm clamp DIN 32676 series B* (adapter possible) |

| Volumen | approx. 60 L |

| Operating pressure | 0 - 6 bar * |

| Pressure backwash | 0 - 2.5 bar |

| Temperature | 5 - 60 °C ** |

| ph range microfiltration *** | 0 - 12 pH (max. 40 °C) I 0 - 13 pH (max. 50 °C) |

| ph range ultrafiltration *** | 1 - 12 pH (max. 40 °C) I 1 - 13 pH (max. 40 °C) |

| Speed | 100 - 450 rpm |

| Pump type | Powerful Eccentric Screw Pump* |

| Connection voltage | 400 V / 50 Hz / 16 A |

| Electrical power | 5000 watts |

| Control | Siemens S7 |

| Dimensions | 1500 x 600 x 1500 mm |

| Weight | approx. 630 kg |