See also

Industries

novoflow GmbH is a renowned provider of filtration systems and solutions used in a variety of industries. The company's innovative filtration and separation solutions have proven to be reliable and efficient, earning popularity among customers worldwide.

The broad range of filtration systems from novoflow is employed by customers in various industries, including food and beverage, chemical and pharmaceutical production, energy and environment, as well as biotechnology.

In this overview, we will provide insights into the different industries where novoflow filtration systems are utilized and how they contribute to enhancing product quality and efficiency.

Job Offers

Laser Safety Cabin

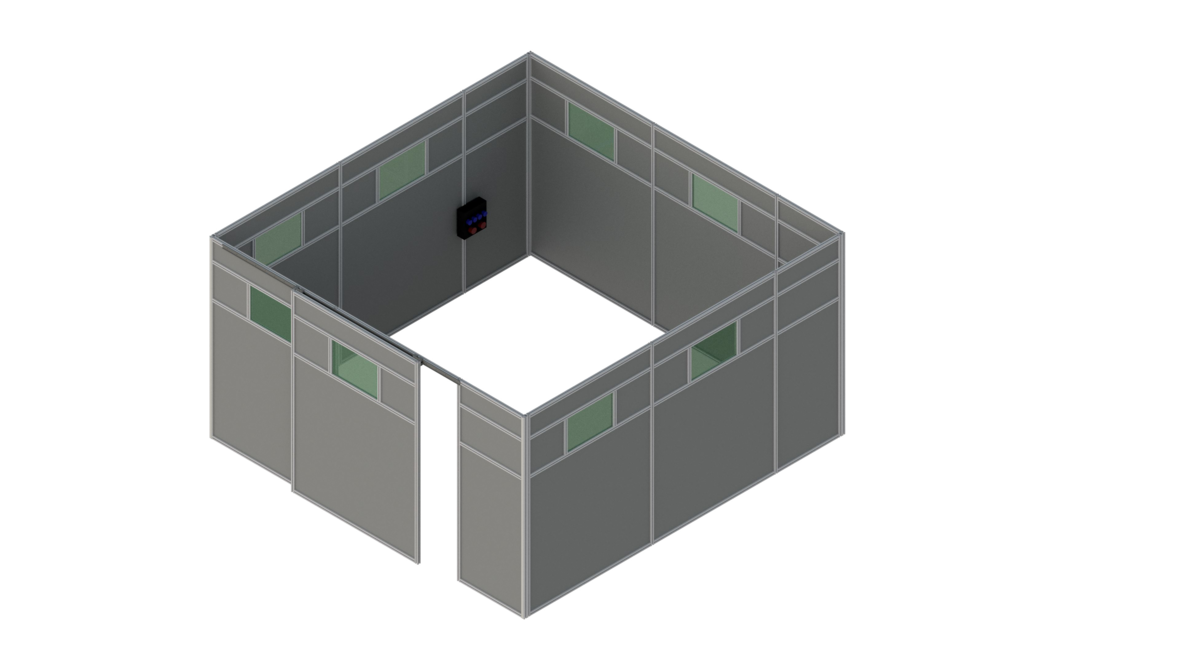

A laser safety cabin reliably separates the laser process from the surrounding area and structures access. novoflow GmbH supplies robust designs with practical safety features that can be adapted to your components and the factory layout. This creates safe workplaces that simplify and manage work processes.

Laser Safety Officer

Laser Safety Officer – Mandatory Training for the Safe Use of Handheld Lasers

At novoflow GmbH, safety is our top priority – especially when using laser welding and laser cleaning equipment. Since every company that uses handheld lasers is required by law to appoint a laser safety officer, appropriate training is essential.

We connect our customers with the Luminus Institute, which offers a certified training course for laser safety officers. The course is aimed at professionals in industry and commerce who work with handheld lasers or in materials processing.

Training content:

✔ Legal and normative requirements (OStrV and TROS)

✔ Identifying and minimizing hazards from Class 4 laser radiation

✔ Planning, implementation, and monitoring of appropriate protective measures

✔ Creating risk assessments and safety concepts

✔ Practical case studies from materials processing The training is delivered flexibly via online videos, allowing participants to acquire the necessary expertise regardless of location and time. Upon successful completion, they will receive a certificate certifying them as qualified laser safety officers. By participating in a certified training course, companies comply with legal requirements and ensure that the use of laser technology in their company meets the highest safety standards. Register now and ensure a safe working environment! Click here for the laser safety officer training!

✔ Identifying and minimizing hazards from Class 4 laser radiation

✔ Planning, implementation, and monitoring of appropriate protective measures

✔ Creating risk assessments and safety concepts

✔ Practical case studies from materials processing The training is delivered flexibly via online videos, allowing participants to acquire the necessary expertise regardless of location and time. Upon successful completion, they will receive a certificate certifying them as qualified laser safety officers. By participating in a certified training course, companies comply with legal requirements and ensure that the use of laser technology in their company meets the highest safety standards. Register now and ensure a safe working environment! Click here for the laser safety officer training!

Laser Welding Machines

A handheld laser welding system from novoflow GmbH focuses highly focused laser energy, penetrating the weld seam with millimeter precision. It combines German engineering with adaptive parameter control, which adapts to changing components in a matter of moments using stored material profiles. This creates spatter-free welds with extremely low heat input, protecting even thin-walled stainless steels from distortion and significantly reducing downstream finishing. In addition, you receive process integration, comprehensive training, and German service from a single source.

Products

Our laser welding and laser cleaning systems are specially designed for demanding industrial applications, offering high performance and precision. These systems are ideal for industries such as automotive, electronics, medical, and aerospace, where precise welding and effective cleaning processes are required.

Our handheld laser welding and laser cleaning systems combine advanced technology in the field of laser welding and laser cleaning. They are user-friendly and efficient, making them indispensable tools in production.

Our systems are equipped with the latest fiber laser technology, ensuring stable performance and a long service life. The laser's high energy density enables precise and deep welds without deformation. Furthermore, even delicate materials such as aluminum or coated surfaces can be processed safely and effectively.

The intuitive user interface and compact design facilitate integration into existing production processes. By automatically adjusting the laser power to the material, consistent results are achieved while minimizing maintenance requirements. This ensures higher productivity and improved profitability.

Thanks to their precise welds and effective surface cleaning, our laser welding and laser cleaning systems meet the high demands of professionals. They contribute to optimizing workflows and helping companies improve their product quality.

Laser Welding and Laser Cleaning

Handheld Laser Welding and Laser Cleaning Machines and Accessories for Professional Applications

News

Here you will find news about environmental and filtration technology from novoflow GmbH. We provide information about our filtration systems and their maintenance, services, job opportunities, and many other topics. Stay up to date and learn more about novoflow. Feel free to contact us directly if you have any questions.