See also

Plant engineer at novoflow (m/f/d)

Plant engineer wanted! – Become part of novoflow and build high-tech plants with us!

Custom plant construction, laser welding, and laser cleaning—the future of modern manufacturing is being created here, and you're right in the middle of it! At novoflow, we are looking for a dedicated Plant engineer (m/f/d) to set up our innovative filtration systems and carry out exciting sample processing using laser technology. If you love technology, enjoy working with modern tools, and want to be part of a future-oriented team, then this is your opportunity!

📍 Place of work: novoflow GmbH, Nelkenweg 10, 86641 Rain 🕒 Employment: Full-time Your tasks: ✅ Construction and assembly of filtration systems in special plant engineering ✅ Reading and implementing technical drawings and plans ✅ Processing samples and components using laser welding and laser cleaning equipment ✅ Performing maintenance and repair work ✅ Identifying and correcting faults or defects in existing systems Your profile: 🔹 Completed training as an industrial mechanic, plant engineer, or comparable qualification 🔹 Experience in mechanical and plant engineering, ideally in special systems engineering 🔹 Knowledge or initial experience with laser welding/laser cleaning is an advantage 🔹 Independent and structured working style 🔹 Ability to work as a team and willingness to travel occasionally 🔹 Good German and English skills are an advantage We offer: ✨ Secure job with a permanent contract ✨ Attractive salary + vacation and Christmas bonuses ✨ 30 days of vacation for your relaxation ✨ Flat hierarchies & motivated team ✨ Work-life balance ✨ Innovative environment with high-tech products ✨ High-quality tools – also for personal use

Custom plant construction, laser welding, and laser cleaning—the future of modern manufacturing is being created here, and you're right in the middle of it! At novoflow, we are looking for a dedicated Plant engineer (m/f/d) to set up our innovative filtration systems and carry out exciting sample processing using laser technology. If you love technology, enjoy working with modern tools, and want to be part of a future-oriented team, then this is your opportunity!

📍 Place of work: novoflow GmbH, Nelkenweg 10, 86641 Rain 🕒 Employment: Full-time Your tasks: ✅ Construction and assembly of filtration systems in special plant engineering ✅ Reading and implementing technical drawings and plans ✅ Processing samples and components using laser welding and laser cleaning equipment ✅ Performing maintenance and repair work ✅ Identifying and correcting faults or defects in existing systems Your profile: 🔹 Completed training as an industrial mechanic, plant engineer, or comparable qualification 🔹 Experience in mechanical and plant engineering, ideally in special systems engineering 🔹 Knowledge or initial experience with laser welding/laser cleaning is an advantage 🔹 Independent and structured working style 🔹 Ability to work as a team and willingness to travel occasionally 🔹 Good German and English skills are an advantage We offer: ✨ Secure job with a permanent contract ✨ Attractive salary + vacation and Christmas bonuses ✨ 30 days of vacation for your relaxation ✨ Flat hierarchies & motivated team ✨ Work-life balance ✨ Innovative environment with high-tech products ✨ High-quality tools – also for personal use

Videos

novoflow GmbH offers a wide selection of application videos for laser welding and laser cleaning. The videos are ideal for beginners and professionals who want to learn more about the applications and advantages of the technologies.

The application videos demonstrate the versatility and efficiency of laser welding and laser cleaning systems. They demonstrate typical applications in various industries and explain the practical advantages of laser technology – from precise work to easy operation of the devices.

Our laser welding and cleaning systems are characterized by high repeatability and low heat generation, which minimizes material distortion and damage. The innovative control technology enables precise adjustment of the laser power to different materials and requirements. This ensures consistently high-quality results and reduces waste in production.

The novoflow team consists of experienced experts who are happy to support you and offer training to ensure the correct use and maintenance of laser welding and laser cleaning systems.

The application videos for laser welding and laser cleaning offer you insight into new developments in laser technology. Discover how these innovative solutions can advance your business and optimize your production processes.

Ceramic Filter Discs

Function

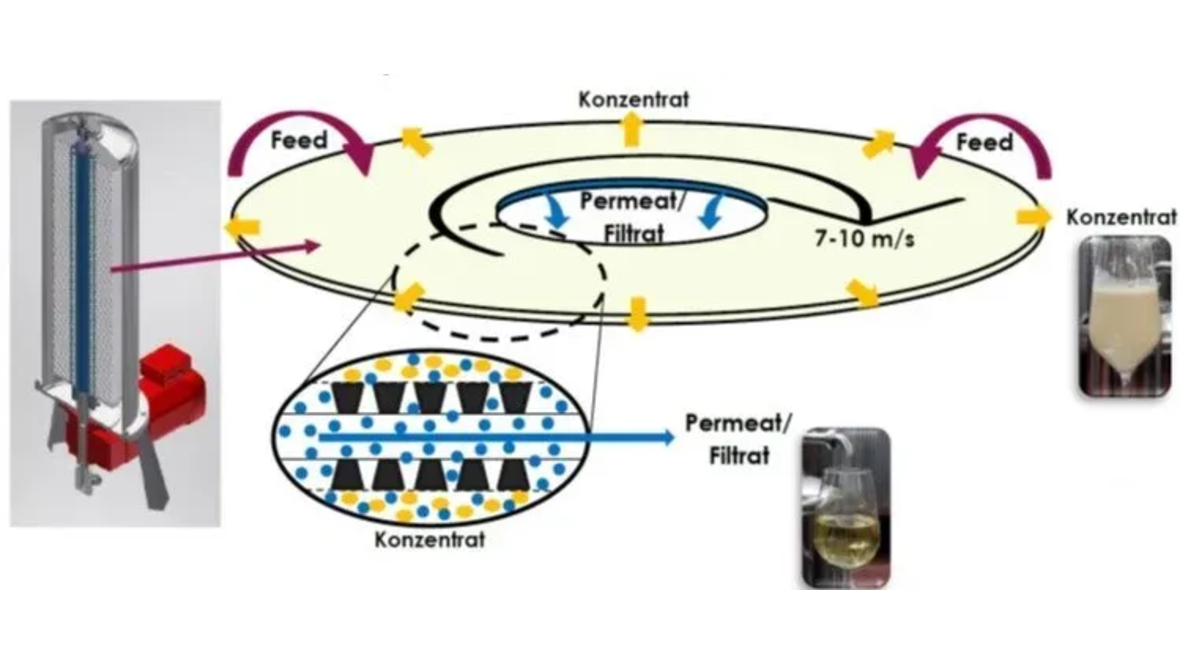

Multiple ceramic filter discs are stacked in a module.

During operation, these stacks rotate to control the cake layer formed during filtration.

The feed through the membrane is divided into two streams: the permeate/filtrate and the concentrate.

Particles larger than the membrane pores are retained and concentrated in the concentrate.

Particles smaller than the membrane pores flow through the porous structure (support) and are collected and discharged in a hollow shaft.

Certificates

Chemical Industry

In the chemical industry, the filtration of liquids and wastewater plays a crucial role in achieving high-quality product standards. The NDCF Dynamic Cross Flow Filtration technology by novoflow GmbH is one of the most advanced solutions, enabling precise and efficient separation of solids and liquids.

The NDCF filtration is based on a specialized nanopore technology capable of removing particles and impurities down to a size of a few nanometers. This technology offers high precision and allows for selective filtration of molecules and particles, which is crucial in the chemical industry.

novoflow GmbH is a leading provider of NDCF filtration technologies, offering a wide range of solutions for various applications in the chemical industry. Our experienced experts are here to assist you in leveraging the benefits of this advanced technology for your specific requirements, enhancing product quality and efficiency.

Customer Service and Maintenance

novoflow GmbH prides itself on not only providing its customers with first-class handheld laser welding equipment and handheld laser cleaning equipment, but also with comprehensive service and support to ensure that their equipment works optimally at all times.

The services offered by novoflow GmbH include the installation and commissioning of their equipment as well as training customers and employees to ensure they can use the equipment safely and effectively. In addition, novoflow GmbH offers a fast and reliable repair service if a device is not working properly.

novoflow GmbH is aware that regular maintenance of the devices is crucial for their optimal performance and longevity. Therefore, the company also offers a professional maintenance service to ensure that the devices are always in perfect condition.

Customers of novoflow GmbH can rely on excellent customer service. The company prides itself on being available to its customers at all times to answer questions or provide support in solving problems.

Overall, novoflow GmbH provides comprehensive service and support for its handheld laser welding and handheld laser cleaning equipment to ensure that its customers always receive the best possible performance and efficiency.