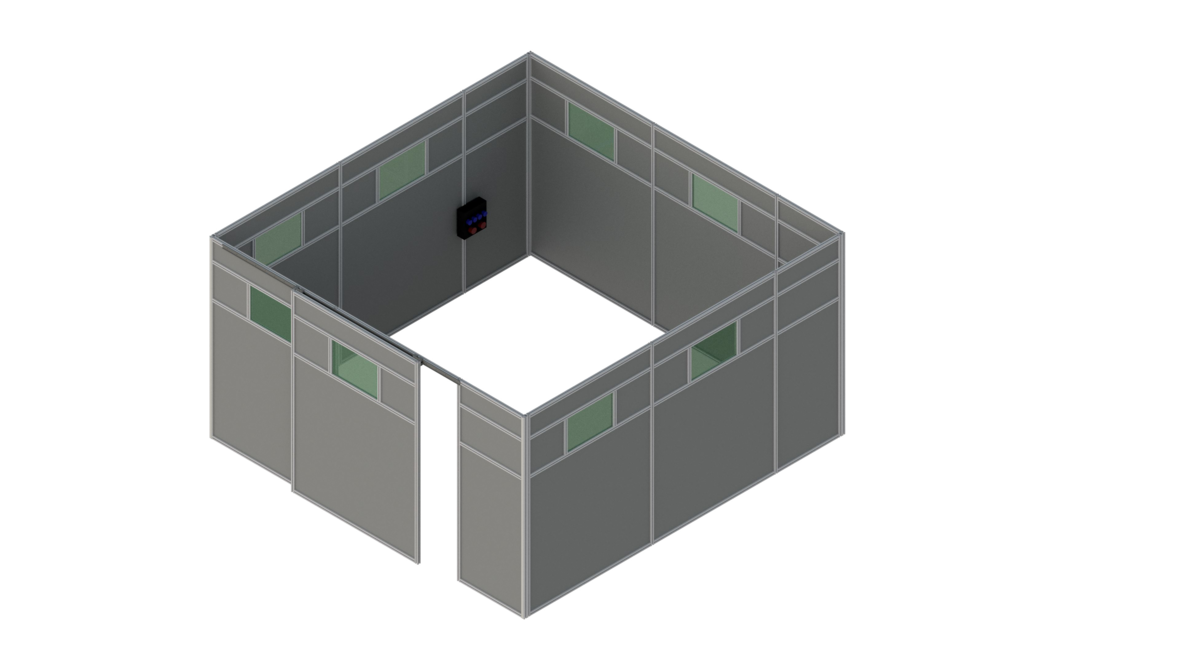

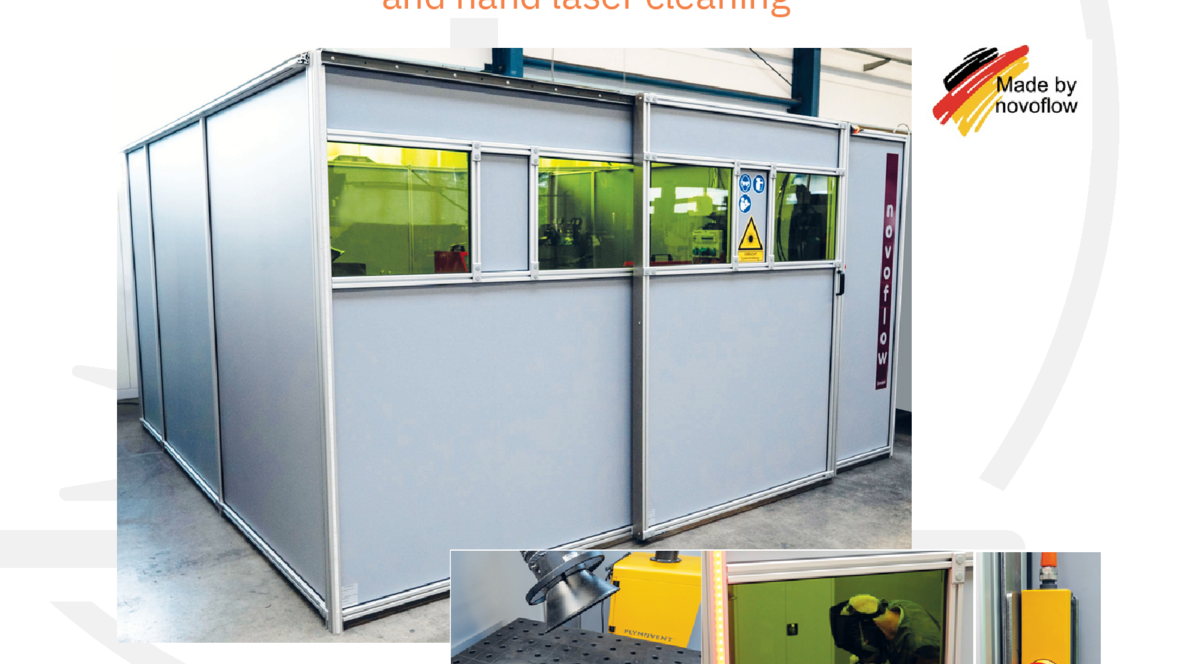

Laser Protection Cabin NF-LSP

Laser safety cabin NF-LSP

A laser safety cabin is a specially designed facility aimed at ensuring the safety of people working with laser systems. Here are some of the main features and characteristics of a laser safety cabin:

The booth is made of special materials that are capable of preventing laser radiation from reaching the outside. Typically, the structure consists of a special coated composite panel.

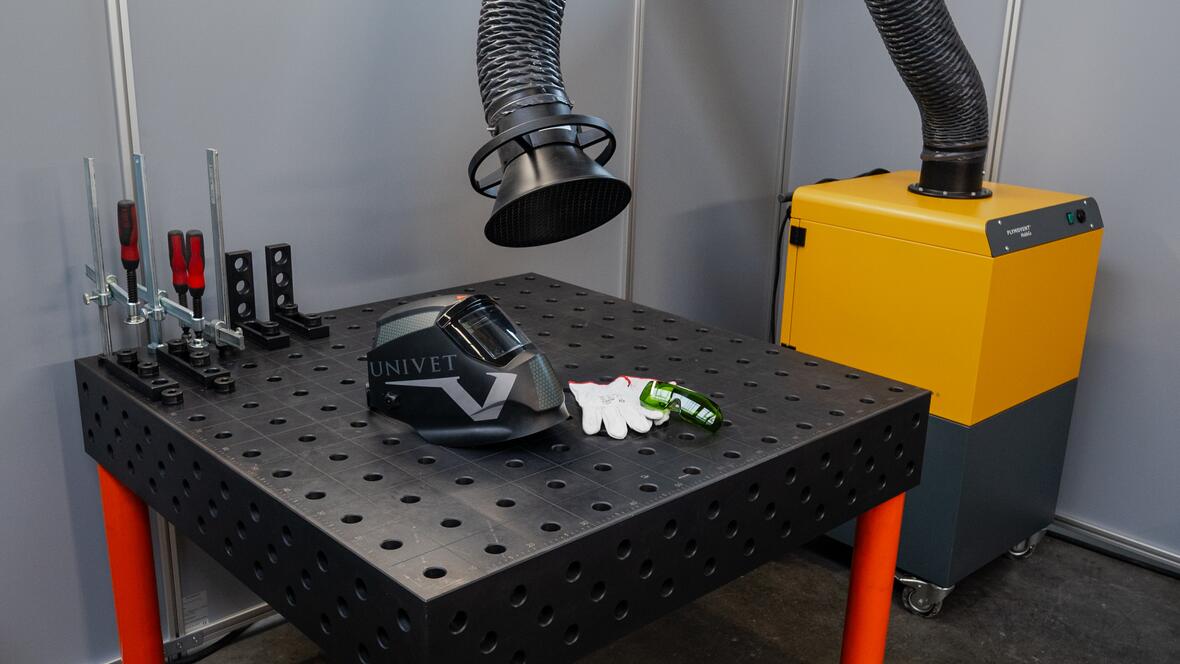

PMMA laser protection window is used in the viewing windows to allow users to observe the laser process inside without exposing them to the risk of direct laser radiation.

Emergency shutdown systems are in place to stop laser operation immediately in the event of an emergency and ensure user safety.

The design and equipment of the laser safety cabin complies with the applicable standards and safety regulations for laser systems to ensure compliance with legal requirements.

Furthermore, an additional extraction system can be integrated and the dimensions of the cabin can be adapted to individual requirements.

Overall, a laser safety cabin provides a safe and controlled environment for the operation of laser systems by minimizing the risk of laser radiation to users and the environment.

More information and technical details can be found in the data sheet under "Downloads".

We reserve the right to make technical changes and changes in shape, color and/or weight within reasonable limits.

Advantages

- Safety: Protection against direct and indirect laser radiation to prevent eye and skin damage.

- Health protection: Minimizing the risk of long-term damage from laser radiation.

- Occupational health and safety: Compliance with occupational health and safety standards to ensure the health of employees.

- Environmental protection: Limiting the spread of laser light outside the work area.

- Precision: Improved control over the laser process by reducing external interference factors such as dirt particles or air currents.

- Avoidance of collisions: Protection against unintended interaction with the laser beam for employees.

- Regulatory compliance: Compliance with regulations and standards for the safe operation of laser systems.

- Efficiency: Optimization of work processes through a dedicated environment for laser applications.

- Reduction of downtime: Minimizing interruptions due to external influences or safety concerns.

- Versatility: Ability to adapt to different laser applications, types and your needs.

- Comfort: Creating a comfortable working environment for employees who regularly work with lasers.

- Long-term cost savings: Preventing damage to equipment and people, resulting in potential savings on repairs and healthcare costs.

- Improving quality: By reducing interference and external influences, laser processes can be more precise and reliable.

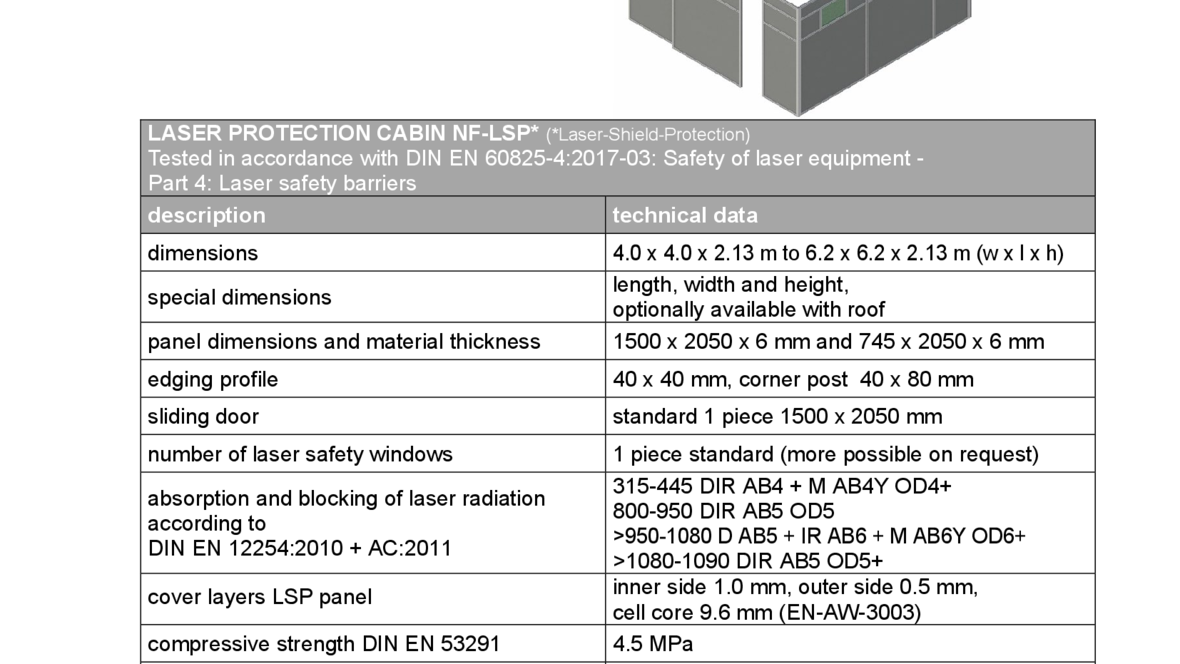

| Model: | NF-LSP* (*Laser-Shield-Protection) |

| Tested: | according to DIN EN 60825-4:2017-03: Safety of laser devices – Part 4: Laser protective walls |

| Dimensions: | 4 x 4 m to 6.2 x 5.4 m |

| Special dimensions: | length, width and height and optionally with a roof |

| Panel dimensions and material thickness: | 1500 x 2050 x 6 mm and 745 x 2050 x 6 mm |

| Edging profile: | 40 x 40 mm, corner post 40 x 80 mm |

| Sliding door: | standard 1 piece 1500 x 2050 mm |

| Number of laser protection windows: | 1 piece standard (more possible on request) |

|

Absorption and blocking of laser radiation DIN EN 12254:2010 + AC:2011: |

315-445 DIR AB4 + M AB4Y OD4+ 800-950 DIR AB5 OD5 >950-1080 D AB5 + IR AB6 + M AB6Y OD6+ >1080-1090 DIR AB5 OD5+ |

| Cover layers LSP panel: | inside 1.0 mm, outside 0.5 mm, cell core 9.6 mm (EN-AW-3003) |

| Compressive strength DIN EN 53291: | 4.5 MPa |

| Fire protection A2 -DIN EN 13501-1: |

A2-s1, D0 classification, non-flammability -A2 - non-flammable -s1 - no smoke development -D0 - no flammable dripping/falling off |

| Exposure limits: |

du - beam diameter 1 mm P - radiant power 1500 – 3000 watts α - beam angle 90° at 1000 mm t - exposure time 1500 W = 60 seconds, 2000W = 45 sec, 3000W = 10 sec Λ - wavelength 700-1400 nm (IR-A) |

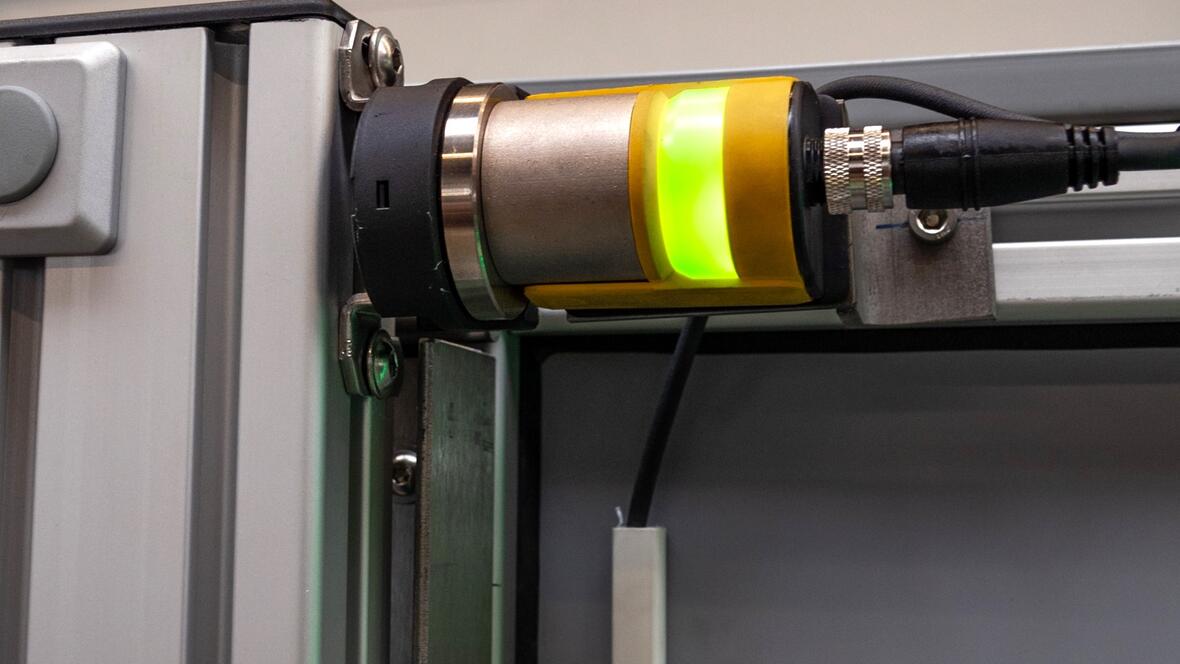

| Access control DIN EN 60825-4:2017-03: |

Electromagnetic guard locking Keyence GS-M Door closed guard locking active (lights up green) Door closed guard locking not active (flashes green) Door opened (lights up red) Locking force approx. 30 N Holding force approx. 500 N |

| Illuminated warning indicators at the entrances to the laser environment according to optical Radiation Protection Ordinance (OSrV): |

LED warning display on both sides left and right Length 2000mm Door closed guard locking active (lights up red) Door open (lights up green) |

| Emergency release: | The emergency release can be used to unlock a door Emergency opening effortlessly, at the same time the Laser source switched off. |

| External safety connection 24 V: | Output for external safety connection of your Laser source. The door must be closed (LED flashes green as soon as the welding or The cleaning process is started on the door automatically locked (luminous green). |

|

Wall distributor EN 61439-1:2011 EN 61439-4:2013 WV4/32 A: |

Rated current: 32 A Rated voltage: 230/400 V Mains frequency: 50/60 Hz Max. load capacity: 22 kW Type of earth connection: TN-C-S Sockets: 4x protective contact 230 V, 2p 1x CEE 16A 400V, 5p 1x CEE 32 A 400 V, 5p Input plug: CEE 32A 400V, 5p Fuse: 1x FI 40 A 4p, 30 mA, 4x LS 230 V/16 A 1p, 1x LS 400 V/16 A 3p IP class: IP44 Dimensions: 28 x 11.8 x 34.9 cm Weight: 3.4kg |

| ATTENTION: | The laser protection composite panels listed here are from novoflow GmbH is a semi-finished product that is intended for further processing. With the primed one (primed) surface that is not provided with a protective film is damage to the Priming cannot always be avoided. Therefore, there is no requirement for it to be optically good Surface. Color uniformity cannot be guaranteed. |