News

Recent news in the field of handheld laser welding and laser cleaning shows that novoflow GmbH has expanded its portfolio with new and advanced hand-held laser welding devices and hand-held laser cleaning devices. These new devices offer higher performance and precision, making them ideal for demanding applications in various industries.

Thanks to the innovative technology, novoflow GmbH can offer its customers customized solutions that guarantee the highest quality and efficiency. The devices are user-friendly and easy to operate, which simplifies and speeds up work processes.

With these new handheld laser welding devices and handheld laser cleaning devices, novoflow GmbH is able to further strengthen its position as a leading supplier of handheld laser welding technologies and meet the increasing demands of its customers.

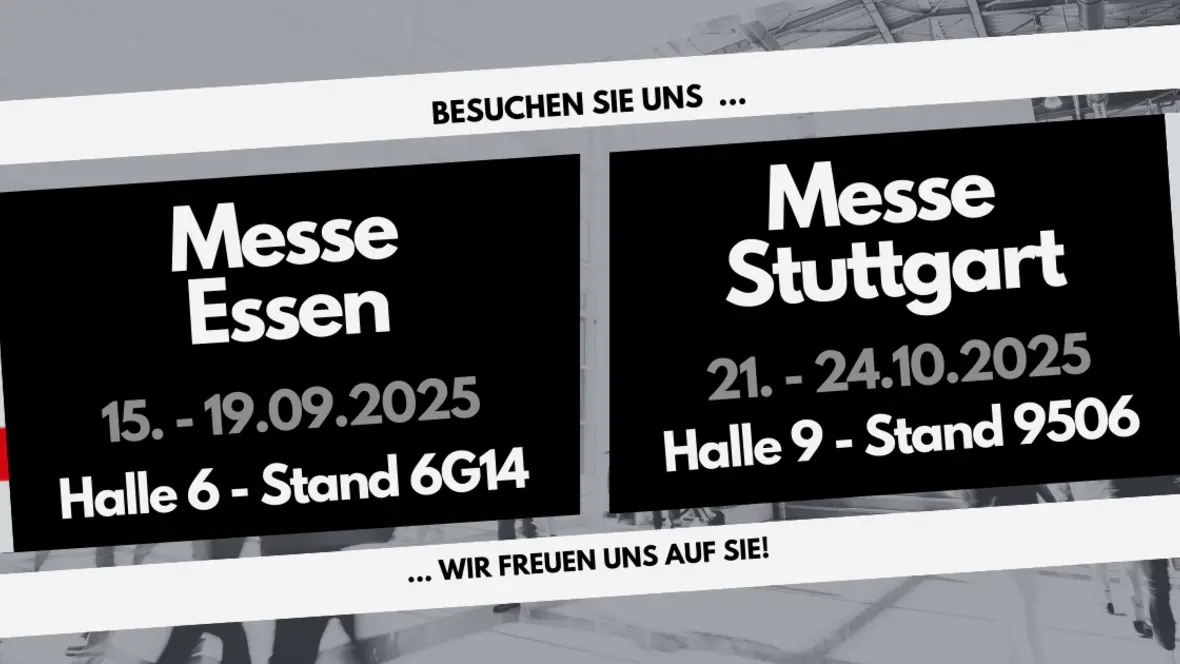

Visit us at the Schweißen & Schneiden and Blechexpo trade fairs

Date: September 15 - 19, 2025

Location: Messe Essen

Hall 6 | Stand 6G14 SCHWEISSEN & SCHNEIDEN is the world's leading trade fair for joining technologies. We present our powerful laser devices for industrial applications that make welding and cleaning processes more efficient and precise. Blechexpo - Stuttgart Trade Fair

Date: October 21 - 24, 2025

Location: Messe Stuttgart

Hall 9 | Stand 9509 At Blechexpo, everything revolves around modern sheet metal processing. We will show you how our hand-held laser cleaning and laser welding solutions process surfaces gently and effectively and enable welded joints of the highest quality. Take the opportunity to experience our technology in action and talk to our experts about your individual requirements.

We look forward to your visit!

Laser welding and laser cleaning: Your safety comes first!

Here are some basic safety instructions: 1. safety goggles & PPE: Always wear suitable safety goggles, face visor helmets or even better an automatic laser safety helmet from novoflow. Protect your eyes and skin! 2. shielded areas: Secure work areas with the novoflow NF-LSP laser safety cabin to protect bystanders. 3. instruction & training: We offer detailed instruction at your site and advanced training specifically geared to your work processes. 4. comply with regulations: Follow all legal requirements and ensure regular maintenance of laser systems. This also includes the timely replacement of wearing parts such as protective lenses. Safety first with novoflow - stay safe and protect yourself and your colleagues!

For more information, contact us.

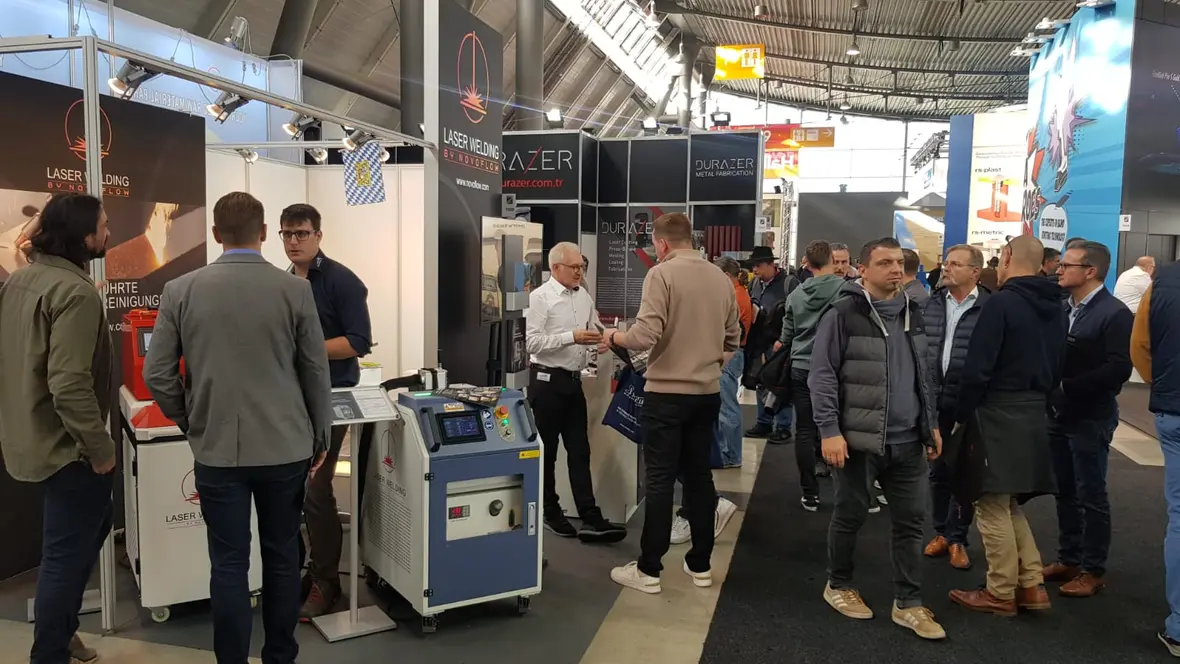

Upcoming trade fairs: novoflow presents innovations

Knowledge transfer days for thermal joining processes

Knowledge transfer days for thermal joining processes

MPA University of Stuttgart

VDI/VDE Innovation + Technik GmbH Interview with Franz Fastner

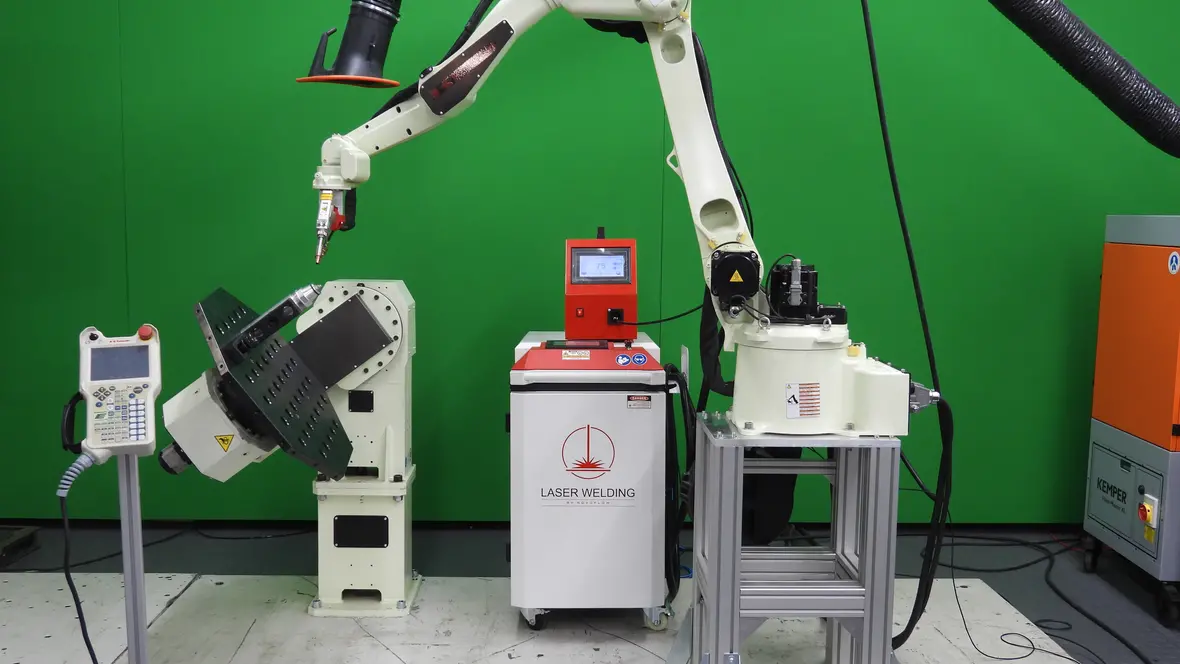

novoflow and the Kawasaki Kobot

Perfect weld seams, maximum precision and speed - this is the future of welding. 💡💪 Whether you work in the automotive industry or in mechanical engineering, this Kobot sets new standards. Discover the versatility and efficiency of laser welding and cleaning with the novoflow hand-held or robot-guided laser welding machines or laser cleaning machines in conjunction with Kawasaki. 🚗 🔧 Discover the future with novoflow and Kawasaki. Video Laser Welding with Kobot Video Laser Cleaning with Kobot