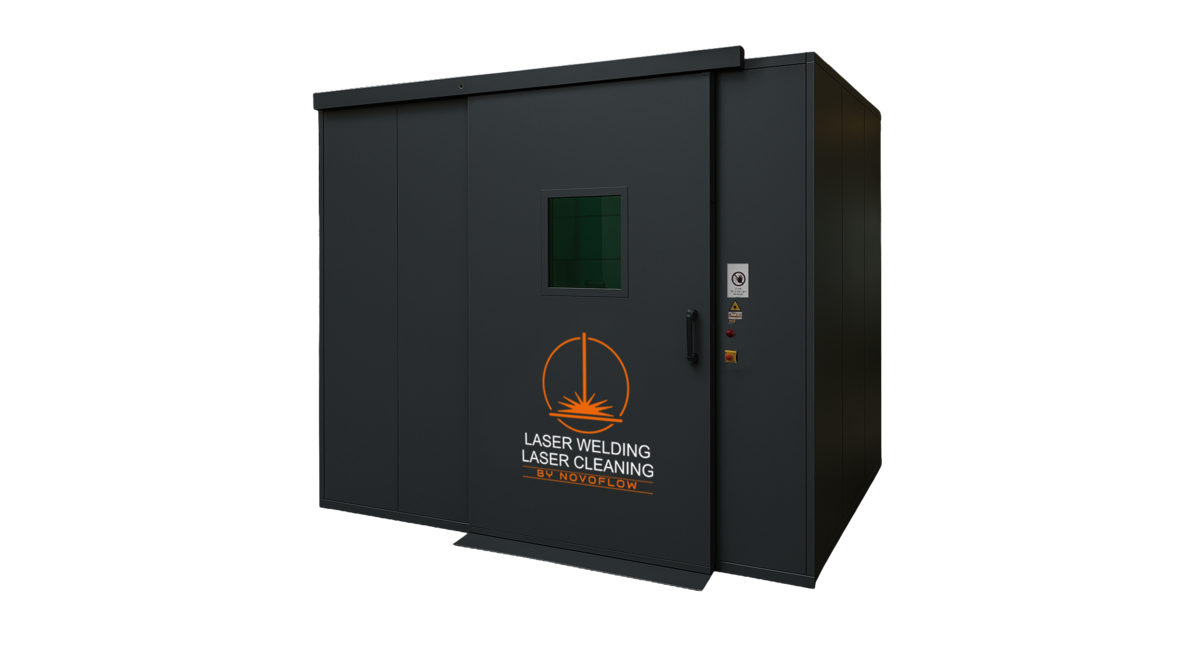

Laser Safety Cabin NF-LSP

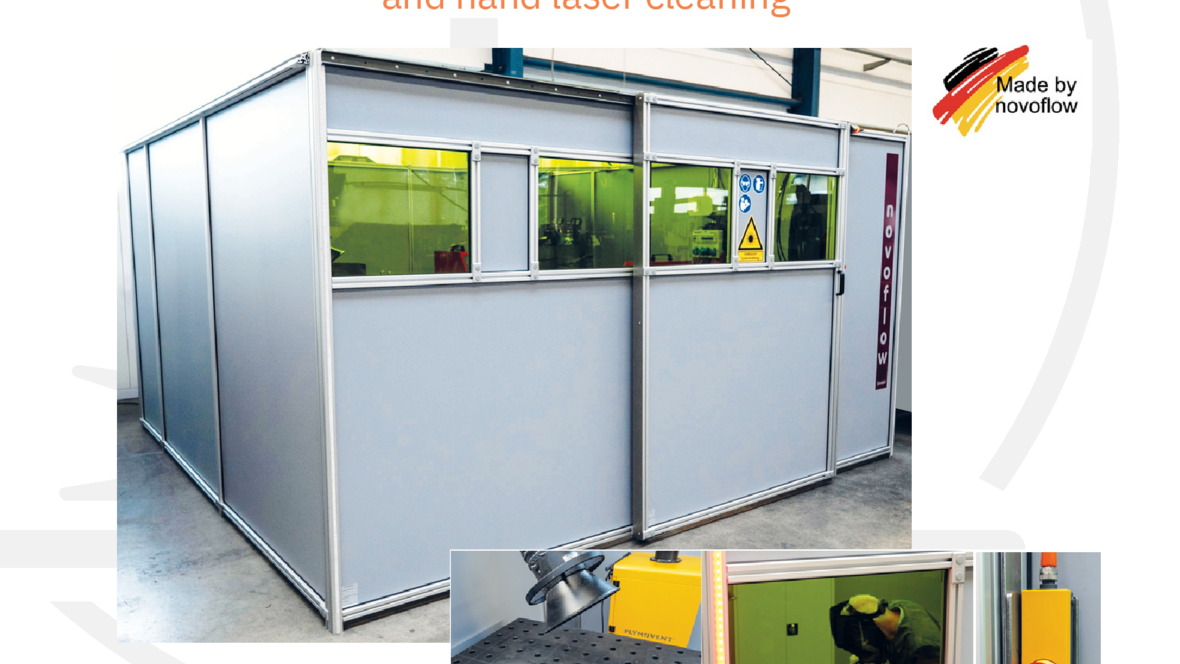

The NF-LSP laser safety cabin was developed for professional use in hand-guided laser welding and laser cleaning. It meets all relevant requirements and is CE certified. This ensures safe operation even with laser powers of up to 3000 watts.

Product specifications:

-

Dimensions: 3850 x 3900 x 2500 / 4000 x 4050 x 3000 / 6125 x 4050 x 3000 mm (custom sizes available upon request)

-

Material: Powder-coated steel sheet in RAL7016

-

Doors: Sliding door with laser-safe bottom seal, opening dimensions depending on cabin size: 1550 x 2375 / 1940 x 2875 / 2620 x 2875 mm (custom sizes available upon request)

-

Windows: PMMA laser protection window, suitable for infrared radiation and tested in accordance with EN 12254 / EN 60825-4 (additional or larger windows available upon request)

-

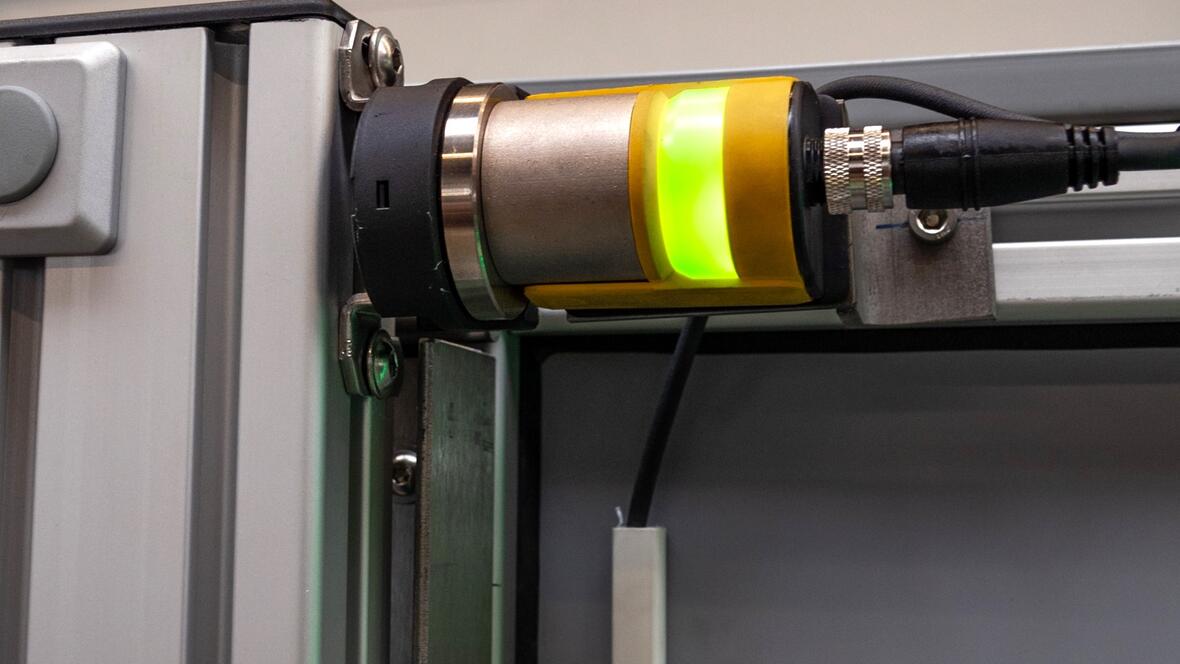

Locking: RFID safety door contact switch, Keyence magnetic lock type 4 according to ISO 14119 *

-

Safety: Dual-circuit emergency stop (built into the device) *

-

Accessories: Control cabinet, media bulkhead (e.g., for power, shielding gas, etc.), storage for personal protective equipment, sockets, safety control unit, laser warning lamp, safety signage, connection options for laser, extraction system, and lighting, cabin lighting with 4 IP65 LED lights, each with 5750 lm, including light switch and without cables to the lights

-

Approval: For laser power up to 3000 watts and a wavelength of 900–1100 nm

-

Delivery: As a kit including 4 corner elements, wall elements, elements for a sliding door, laser safety window, mounting kit, operating instructions with assembly instructions, parts list, EU declaration of conformity with CE marking (on-site assembly available upon request)

-

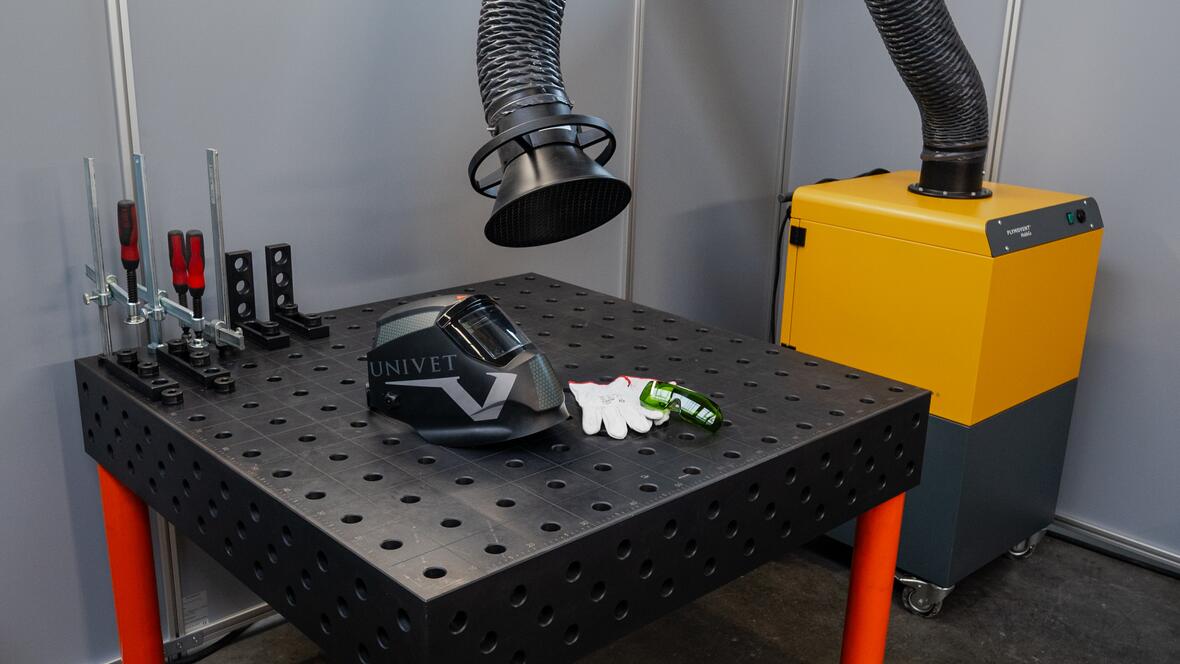

Optional: Extraction system, roof (with support rails, cover, extraction bracket, mounting kit), on-site assembly, PPE (personal protective equipment), welding table, novoflow laser welding machine, novoflow laser cleaning machine, dual-circuit emergency stop*, safety door contact switch*

Features and benefits:

-

Protection: Reliable protection against scattered radiation and reflections for people and the environment

-

Process stability: Reduction of external interference factors such as dirt particles or air currents

-

Flexibility: Cabin available in 3 standard sizes—see Technical Data (special sizes available on request)

-

Safety: CE-certified and tested in accordance with relevant standards

- Areas of application: For industrial hand laser welding and hand laser cleaning in manufacturing plants, workshops, and for repair and service work with increased safety requirements

We offer a wide range of accessories and safety equipment for our laser welding systems – complemented by expert service and technical support.

If you require a laser safety officer, we offer direct placement through our website – further information can be found under Laser Safety Officer Training.

Technical modifications as well as changes in shape, color and/or weight are subject to reasonable variations.

* These components are not part of the laser safety cabin. They are normally supplied with novoflow laser welding machines and laser cleaning machines, but can also be obtained separately from us upon request.These components are not included in the laser safety cabin, but are supplied with the novoflow laser welding devices or laser cleaning devices.

| Model: | NF-LSP |

| Standard sizes (W x L x H -approximate dimensions): |

3850 x 3900 x 2500 mm - Item No. 2747 4000 x 4050 x 3000 mm - Item No. 2748 6125 x 4050 x 3000 mm - Item No. 2749 |

| Special sizes: | Length, width, and height are optionally customizable upon request |

| Tested according to: |

DIN EN ISO 12100:2011-03: Machine safety - General design principles - Risk assessment and risk reduction DIN EN ISO 11553-2:2009-03: Machine safety - Laser processing machines - Part 2: Safety requirements for handheld laser processing equipment DIN EN 12254:2012-04: Shielding at laser workstations - Safety requirements and testing DIN EN 60825-4:2025-09: Safety of laser equipment - Part 4: Laser safety walls DIN EN ISO 13849-1:2023-12: Machine safety - Safety-related parts of control systems - General design principles DIN EN 60204-1:2019-06: Machine safety - Electrical equipment of machines |

| Sliding door: | including 1 smooth-running sliding door, with laser-safe sealing of the floor area, opening dimensions depending on cabin size: 1550 x 2375 / 1940 x 2875 / 2620 x 2875 mm |

| Laser safety window: | Including 1 laser safety window OD 6+ 1064-1100 nm, suitable for infrared use and tested according to DIN EN 12254 / EN 60825-4 and CE certified, 300 x 450 mm (other sizes available on request) |

| Access control* according to DIN EN 60825-4:2017-03: | Keyence GS-M electromagnetic door contact switch* Door closed: Interlock active (green light) Door closed: Interlock inactive (flashing green) Door open: (red light) Interlocking force: approx. 30 N Holding force: approx. 500 N |

| Emergency release* (dual-circuit emergency stop): | Emergency release (dual-circuit emergency stop)* allows the door to be opened effortlessly in an emergency and simultaneously switches off the laser source. |

| Exposure limits: | T3 (10 s) |

| Fire protection: | DIN 4101-1/13501-1 A1: non-flammable |

| External safety connection 24 V: | Output for the external safety connection of your laser source. The door must be closed (LED flashes green). As soon as the welding or cleaning process starts, the door will lock automatically (LED stays lit green). |

| Scope of delivery: |

4 corner elements, wall elements, elements for a sliding door, laser safety window, made of powder-coated sheet steel RAL 7016 includes mounting kit, operating instructions with assembly instructions, parts list, EU declaration of conformity with CE marking includes safety package with control cabinet, media bulkhead (e.g., for electricity, inert gas, etc.), storage for personal protective equipment, complete safety signage, safety control unit, sockets, laser warning lamp, laser connection, extraction system, and lighting includes cabin lighting with 4 IP65 LED lights, each with 5750 lm, including light switch (excluding cables to the lights) - includes pre-assembly and packaging |

| Optional: |

- Extraction system - Roof (with support rails, overlaps, extraction brackets, and mounting kit) - On-site assembly - Personal protective equipment (PPE) - Welding table - novoflow laser welding and/or laser cleaning unit - Emergency release (dual-circuit emergency stop)* - Safety door contact switch* |

| We will be happy to provide you with the technical data sheets as a PDF on request. | |

| * These components are not part of the laser safety cabin. They are normally supplied with novoflow laser welding machines and laser cleaning machines, but can also be obtained separately from us upon request. | |

Would you like to know more?

Get in touch via Email: kontakt@novoflow.com , Phone: +49 90 90 / 70 11 50 or Contact form