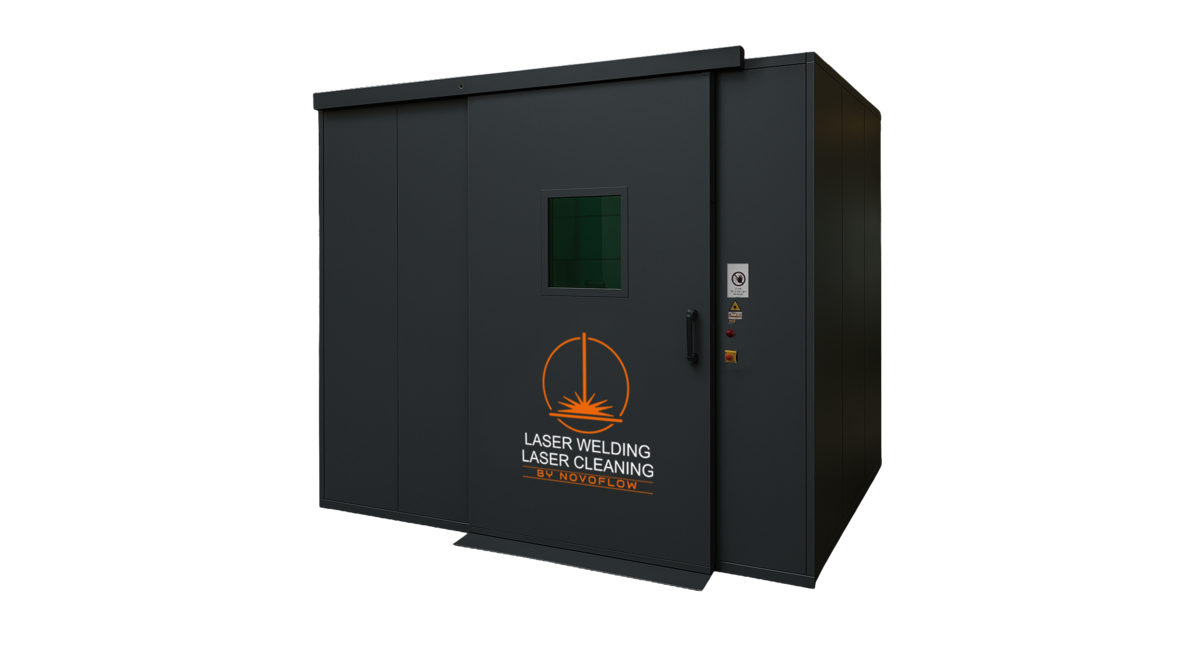

Laser Safety Cabin from novoflow: Your safe space

A laser safety cabin reliably separates the laser process from the surrounding area and structures access. novoflow GmbH supplies robust designs with practical safety features that can be adapted to your components and the factory layout. This creates safe workplaces that simplify and manage work processes.

NF-LSP

What a laser safety cabin does in everyday life

In everyday production, the booth protects people, equipment, and materials by clearly demarcating the laser area and reducing external interference such as dirt particles or air currents. This reduces risks, increases process stability, and ensures compliance with quality standards.

Security features that count

The equipment depends on the application and environment; however, key elements are standardized and easy to operate.

· Emergency stop (redundant – included with the laser device) with clear feedback for quick, safe shutdown.

· Emission warning lights (depending on the model) that clearly indicate the operating status.

· Monitoring of the safety doors (e.g., via contact switches) for locking and process release.

· Robust panels for effective shielding of the laser room.

· Laser protection windows allow for observation of the laser process inside.

This feature builds confidence and reduces operating errors. For details on variants and scope of delivery, please use the contact form.

Viewing windows and standards – check safely

Viewing windows allow for process observation without compromising shielding. Combined with standard-compliant components - PMMA laser safety windows in accordance with EN 12254 and 60825-4—this ensures control and quality assurance at all times.

Modular laser safety cabin: grows with your production

The modular design allows for adjustments when component sizes, cycle times or layouts change.

· Segmented design for on-site expansion or modification.

· Replaceable panels for windows, connections, and service openings.

· Cable and media routing with easily accessible interfaces.

This ensures that your laser safety booth remains suitable and cost-effective in the long term.

Laser enclosure and integration into cells

For automated processes, interfaces are defined that connect the booth and peripherals into a consistent system.

· Access via sliding door

· Signals for release, fault, and status for connection to HMI and PLC

· Extraction and lighting tailored to the component and process

This provides you with a laser safety cabin that combines maximum safety with ease of use. We offer not only the right booth, but also the optimally matched laser welding machines or laser cleaning machines – all from a single source.

Options and accessories for your protection cabin

Additional modules refine ergonomics, safety and monitoring.

· Extraction and filter modules tailored to the process particle load.

· Lighting for improved visibility.

· Roof for protecting employees working on bridges or platforms.

· Additional laser safety windows to provide greater visibility or light.

This allows you to specifically complement what your application requires. We are happy to provide a tailored recommendation. Contact us using the contact form.

Experience technology: demonstrations and videos

Demonstrations with your components show how the booth, device, and process interact. Video examples also explain parameters and typical tasks. This allows you to make decisions based on real-life experience.

· Live demos of our in-house booth allow you to see for yourself.

· Video clips explaining how our laser safety booth works.

You can get more insight in the application videos.

novoflow GmbH – Quality, Precision & Innovation

novoflow GmbH has been developing filtration solutions since 2004 and, for several years now, also robust systems for handheld laser welding and laser cleaning at its Rain am Lech site in Bavaria. ISO 9001-certified processes, a global partner network, and awards such as the Bavarian Export Award underscore its long-term innovative strength.

· ISO 9001:2015 – comprehensive documentation of all production steps

· Bavarian Export Award – recognition for international market success

· Bavarian State Award 2005 & 2008 – awards for outstanding technical achievements

These key figures provide you with planning security and ensure a scalable partnership. Learn more about our company on the Company page.

Our customer service also provides long-term support – from installation to rapid assistance, we're always there for you. Our news section keeps you up-to-date with the latest news from the laser welding and laser cleaning industries.

This way, you get not just a laser protection cabin, but a fully supported solution that ensures your long-term success.

Request advice now

We would be happy to review your application and outline a suitable cabin concept, including options. Call us at +49 9090 / 701150, write to info@novoflow.com, or use the contact form.

FAQ about laser safety cabins

Below we answer the most frequently asked questions about selection, installation and operation.

When does modular construction make sense?

When component sizes or cycle times are subject to change, segments can be added, windows relocated, and interfaces retrofitted without completely replacing the cabin. This ensures the system remains adaptable over the long term.

Why are viewing windows important?

They allow process monitoring and facilitate testing, instruction, and quality control. When combined with suitable protective screens, shielding is maintained and audit requirements can be documented and met.

How does the installation typically proceed?

After clarifying the location, media, and access requirements, installation is carried out in preconfigured steps as a kit or by booking a custom installation, which is carried out by our team. Finally, functions are tested and your team is briefed. This ensures a planned start to operations.